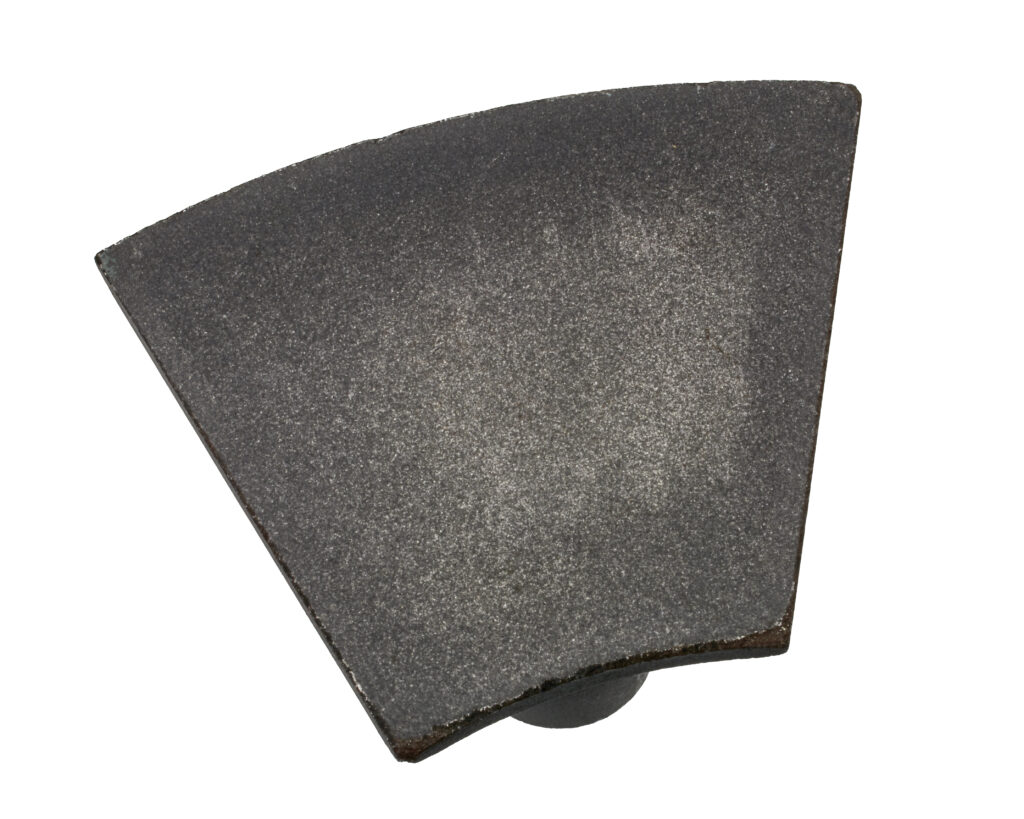

Amsted Automotive has more than 20 years of leading development in both the engineering and manufacturing of SMA & SMC. The process specializes in compaction and heat treatment of complex components to optimize electromagnetic properties and expand soft magnetic applications possibilities.

Key Features:

- Our tight tolerances and net-shaped capabilities reduce material waste, making our components superior to those made using lamination stack technology.

Advantages:

- Our SMA components are designed for high density and permeability, which is ideal for precision applications requiring consistent magnetic responses.

- Our dedicated testing equipment has helped us to produce over 30 million pieces and guarantees precision and consistency.

- Offer detailed guidance on product design and pressing large-diameter parts for applications such as axial flux motors and high-frequency actuators.

Ready to Connect?

Tell us a bit about your project, and our team will follow up with the details needed to move the conversation forward.

We look forward to hearing from you.

Powder Metallurgy Capabilities

Our advanced in-house capabilities allow for design and system simplification, maximizing cost savings and performance. Ideal for intricate geometries & complex shapes, our Powdered Metal products deliver the flexibility engineering teams need to realize cutting-edge product designs and manufacturing goals—with extensive expertise in producing high-density products.

Contact us to see how Amsted Automotive’s Powdered Metal products can enhance your designs and innovations.

Get the latest from our design, engineering, and manufacturing teams.

Recent News

Amsted Automotive Leads the Industry with U.S.-Manufactured Cutting Tools for Mining and Construction

Amsted Automotive continues to set the standard for industrial strength, quality and resiliency through its commitment to U.S.-based manufacturing of cutting tools. As the only…

Amsted Automotive Wins Michigan Manufactured Export of the Year Award with Innovative One-Way Clutch

Amsted Automotive was honored with the Michigan Manufactured Export of the Year award, presented by the Michigan Manufacturers Association (MMA) recognizing the company’s leadership in…

Amsted Automotive Showcases Industry-Leading Manufacturing Capabilities at the 2025 MEMA OE Suppliers Annual Conference

Amsted Automotive will highlight its global engineering and manufacturing capabilities at the 2025 MEMA OE Suppliers Annual Conference November 19-20, 2025, displaying examples and information…

Amsted Automotive Honored with Manufacturer of the Year Award

Amsted Automotive has been named the 2025 John G. Thodis Michigan Manufacturer of the Year – Large Tier by the Michigan Manufacturers Association (MMA). The…