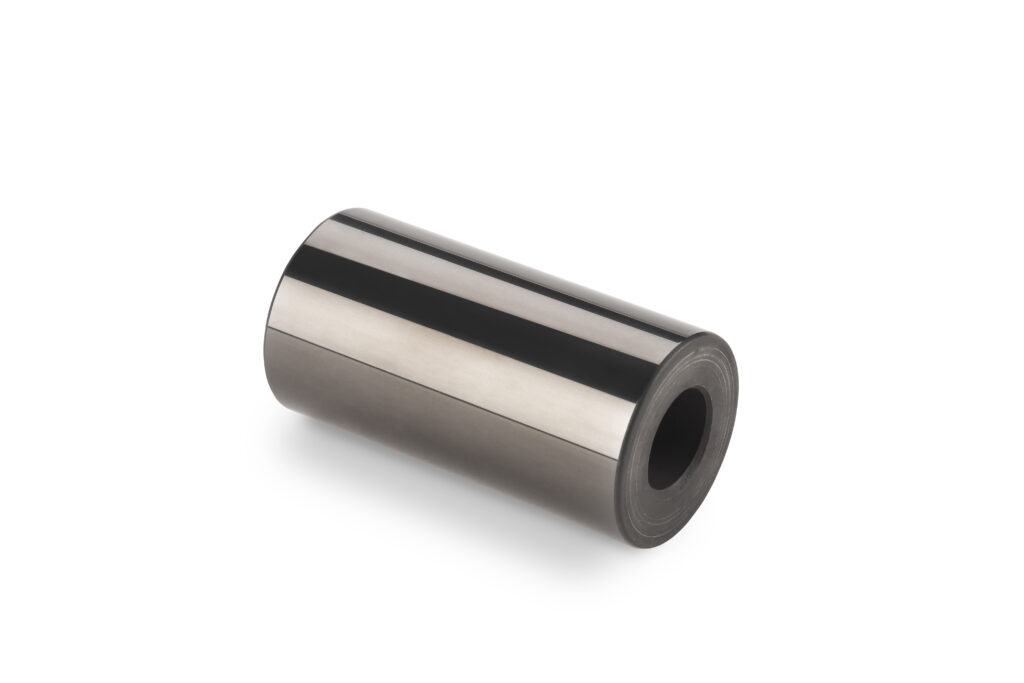

For over 120 years, we have specialized in developing and manufacturing piston pins and bearing products for the internal combustion, hybrid and electric vehicle markets. Our dedicated team of engineers matches our established reputation for quality, reliability, value and our global presence ensures unmatched capacity, capabilities, consistency and cost efficiencies for customers worldwide.

- Largest piston pin manufacturing facility by volume in the world.

- Serves as global product design, process technology development, and innovation center.

- Only location in the world with an in-house DLC production supplier creating an integrated, streamlined process.

- Market leader in North America for automotive and medium duty pins due to technology, scale, quality, and dependability.

- Upgraded grinding capability to meet sophisticated design requirements.

- Largest independent piston pin producer in the European region with a strong relationship with key suppliers.

- Capability to meet multi-national product requirements.

Markets Served:

- Automotive

- Medium Commercial Vehicles

- Heavy Duty Commercial Vehicles

- Aerospace

- Power Generation

- Agriculture

- Off-Highway

- Recreational Vehicles

Cold Forming Capabilities

We are leaders in cold-forming, delivering advanced solutions that enhance material efficiency, reduce secondary operations, and outperform traditional machining. Our expertise and net-shaping technologies enable us to produce stronger, more durable components with intricate geometries and complex piercings.

Our cold-forming process preserves uninterrupted grain flow for superior strength and reliability as we partner with leading industrial and automotive manufacturers to meet the most demanding applications.

Contact us to discover more about our expert cold-forming solutions.

Get the latest from our design, engineering, and manufacturing teams.

Recent News

Amsted Automotive Powder Metallurgy Innovation Recognized with MPIF Award of Distinction

Amsted Automotive’s Burgess-Norton powder metal business has earned a 2025 Award of Distinction from the Metal Powder Industries Federation (MPIF) for its outstanding achievement in…

Amsted Automotive Honored with 2024 Honda Excellence in Quality and Delivery Award for Second Time in Five Years

Amsted Automotive has been recognized with the prestigious 2024 Honda Excellence in Quality and Delivery award, marking the second time in five years that the…

Amsted Automotive Displays Diverse Powertrain Technologies for ICE, HEV and EV Platforms at 2025 VDI Dritev

As hybrid electric vehicles (HEV) rapidly gain traction alongside internal combustion engine (ICE) and battery electric vehicle (BEV) platforms, the powertrain landscape is undergoing a…

Amsted Automotive Brings its Advanced Powertrain Efficiency Solutions and Metal-Forming Capabilities to China for TMC 2025

China’s automotive industry is evolving at an unprecedented pace, driven by rapid advancements in electrification, stricter efficiency standards, and a strong push toward sustainable mobility….