Amsted Automotive designs and manufactures precision-engineered gears that deliver superior density, optimized performance, and enhanced durability.

Our expertise in gear technology ensures components are manufactured to exceed industry standards, incorporating advanced grinding, tooth profile optimization, and innovative manufacturing techniques to eliminate unnecessary secondary operations.

Helical Gears

- Manufactured to AGMA Class A8, with higher density.

- Proven gear teeth optimization and finish OD/ID grinding.

- Offers double press/double sinter operations.

- Elimination of secondary operations on the tooth profile while producing parts with superior density and performance.

- Design for manufacturability.

- Offering customers tailored solutions that exceed standard print specifications.

Pump Gears

- Over 25 years of experience in gear design.

- Critical in fluid systems such as fuel and coolant pumps.

- Rigorous optimization for gear teeth form.

- Finish-ground for high precision.

Ring Gears

- Gear teeth optimization process and finish grinding ensure that each Ring Gear delivers high tolerance and performance.

- Crafted with high density to meet higher AGMA Class standards.

- Design flexibility allows us to modify the geometry to add spline link features without an added machining process.

- Design for manufacturability.

- Creates solutions beyond simple print requirements, ensuring every component performs reliably under pressure.

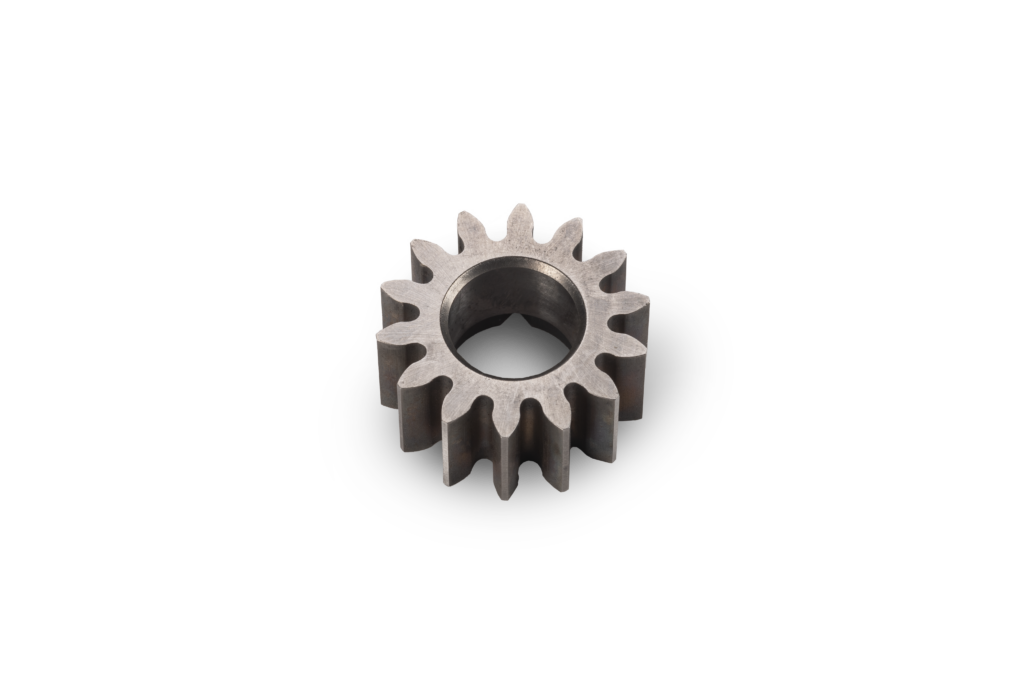

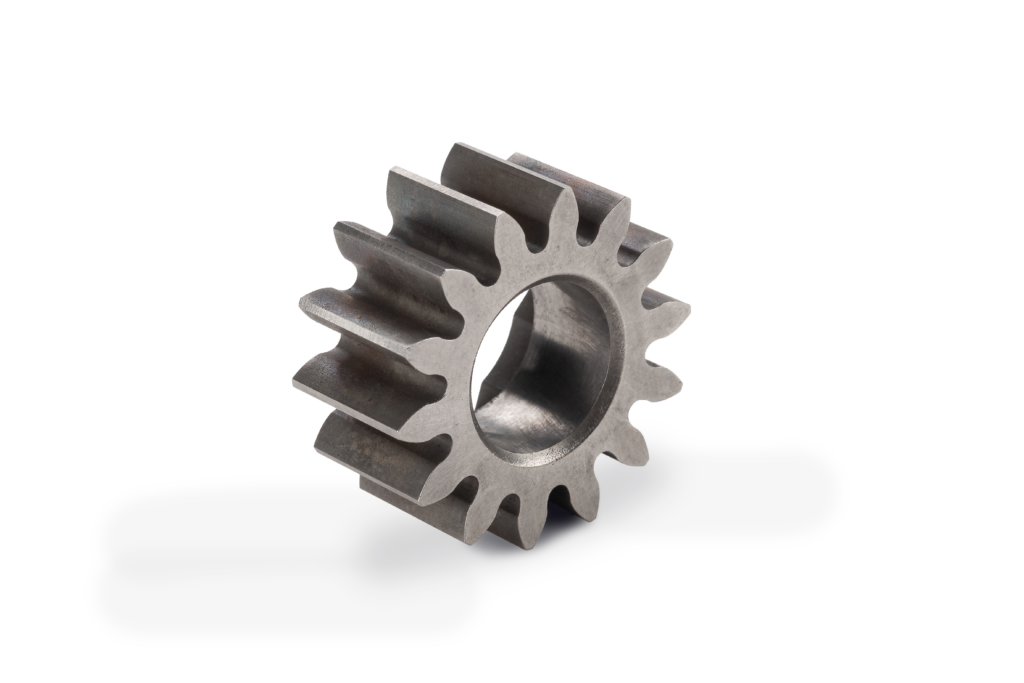

Sun Gears

- Crafted for planetary gear systems, providing high-density performance to low torque applications.

- Optimized gear teeth and precision grinding.

- Designed to handle the demands of high-stress applications.

- Expertise in double press and double sinter operations.

Ready to Connect?

Tell us a bit about your project, and our team will follow up with the details needed to move the conversation forward.

We look forward to hearing from you.

Powder Metallurgy Capabilities

Our advanced in-house capabilities allow for design and system simplification, maximizing cost savings and performance. Ideal for intricate geometries & complex shapes, our Powdered Metal products deliver the flexibility engineering teams need to realize cutting-edge product designs and manufacturing goals—with extensive expertise in producing high-density products.

Contact us to see how Amsted Automotive’s Powdered Metal products can enhance your designs and innovations.

Get the latest from our design, engineering, and manufacturing teams.

Recent News

Amsted Automotive Mining Construction and Industrial Solutions Will be Showcased at CONEXPO 2026

Amsted Automotive will exhibit its innovative net-formed products for the construction, mining and heavy-equipment markets at CONEXPO-CON/AGG 2026 taking place March 3–7 in Las Vegas.

Amsted Automotive Leads the Industry with U.S.-Manufactured Cutting Tools for Mining and Construction

Amsted Automotive continues to set the standard for industrial strength, quality and resiliency through its commitment to U.S.-based manufacturing of cutting tools. As the only…

Amsted Automotive Wins Michigan Manufactured Export of the Year Award with Innovative One-Way Clutch

Amsted Automotive was honored with the Michigan Manufactured Export of the Year award, presented by the Michigan Manufacturers Association (MMA) recognizing the company’s leadership in…

Amsted Automotive Showcases Industry-Leading Manufacturing Capabilities at the 2025 MEMA OE Suppliers Annual Conference

Amsted Automotive will highlight its global engineering and manufacturing capabilities at the 2025 MEMA OE Suppliers Annual Conference November 19-20, 2025, displaying examples and information…