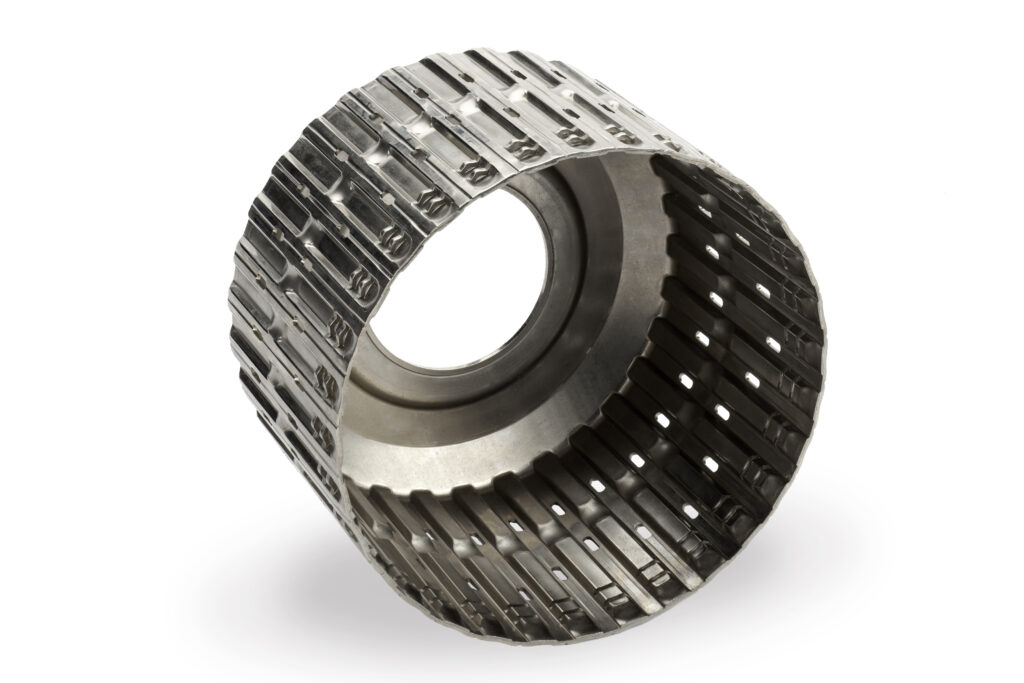

Amsted Automotive sets the benchmark in clutch component manufacturing, utilizing flow-forming and hoop-band technologies as advanced alternatives to traditional stamped components. We enable high-precision, high-durability designs that outperform conventional manufacturing methods by leveraging grob, roller-die and flow-forming capabilities.

Our clutch hubs and disc carriers are engineered for exceptional precision, durability, and lightweight performance. With dimensions of Ø330mm x 275mm*, these components integrate advanced manufacturing techniques to achieve optimal strength, weight reduction, and cost efficiency.

Disc Carriers & Clutch Hubs

Key Features:

- High Precision: Machined to ±0.03mm* and stamped/flow-formed to 0.1mm* tolerances, ensuring superior performance and reliability.

- Durable Materials: Manufactured from high-strength, low-alloy (HSLA) steel and aluminum, providing work hardening, long-term durability, and lightweight efficiency.

Advantages:

- Advanced Manufacturing Processes: Incorporates in-die spline forming, flow forming, grob forming, and roller-die technologies, allowing for flexible solutions for low- to high-volume production.

- Customizable Design: Engineered to meet specific volume, form, and function requirements.

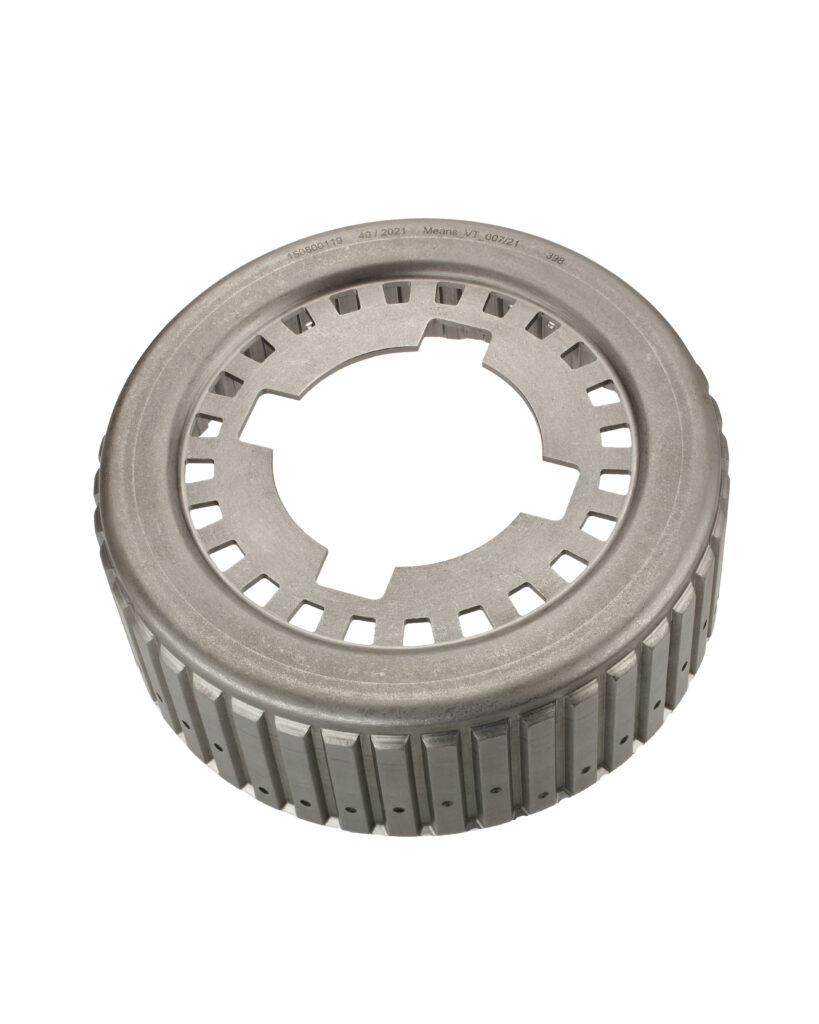

Aluminum Housings

Our Aluminum Housings are designed to deliver exceptional durability, strength, and production efficiency. At Ø220mm x 275mm*, these components enable higher performance and greater production flexibility.

Key Features:

- Precision Stamping: Machined to 0.03mm* and stamped/flow-formed to 0.15mm* tolerances, ensuring consistent accuracy and superior performance.

- Advanced Materials: Manufactured from high-strength low-alloy (HSLA) steel and aluminum, offering work hardening, long-term durability, and lightweight efficiency.

- Advanced Processes: Machining, automated deburring, anodizing, assembly, and automated inspection for streamlined production and rigorous quality assurance.

Advantages:

- Scalable Manufacturing: In-die spline forming, flow forming, and grob forming technologies enable flexible production from low to high volumes.

- Weldable Solutions: Components can be welded to meet precise design and application requirements, providing versatile integration across propulsion systems.

- Scalable Production: Designed to support high-volume manufacturing and custom production requirements, ensuring flexibility and efficiency.

- Stamping Capabilities: Eliminates the need for machining while maintaining tight tolerances.

*Product specifications reflect a subset of our capabilities.

Advanced Metal Forming Capabilities

Specializing in cutting-edge processes like flow forming, in-die spline forming, grob forming, laser welding and stampings, our advanced metal forming expertise enables us to produce highly complex components and assemblies that meet the demands of next-generation powertrain hybrid and EV architectures for automotive, off-highway, and industrial applications.

Our innovative solutions are designed to improve performance and manufacturability, reduce weight and enhance durability through the use of production methods that allow for customized solutions.

Contact us to discover why Amsted Automotive is the market leader in Advanced Metal Forming.

Get the latest from our design, engineering, and manufacturing teams.

Recent News

Amsted Automotive Powder Metallurgy Innovation Recognized with MPIF Award of Distinction

Amsted Automotive’s Burgess-Norton powder metal business has earned a 2025 Award of Distinction from the Metal Powder Industries Federation (MPIF) for its outstanding achievement in…

Amsted Automotive Honored with 2024 Honda Excellence in Quality and Delivery Award for Second Time in Five Years

Amsted Automotive has been recognized with the prestigious 2024 Honda Excellence in Quality and Delivery award, marking the second time in five years that the…

Amsted Automotive Displays Diverse Powertrain Technologies for ICE, HEV and EV Platforms at 2025 VDI Dritev

As hybrid electric vehicles (HEV) rapidly gain traction alongside internal combustion engine (ICE) and battery electric vehicle (BEV) platforms, the powertrain landscape is undergoing a…

Amsted Automotive Brings its Advanced Powertrain Efficiency Solutions and Metal-Forming Capabilities to China for TMC 2025

China’s automotive industry is evolving at an unprecedented pace, driven by rapid advancements in electrification, stricter efficiency standards, and a strong push toward sustainable mobility….