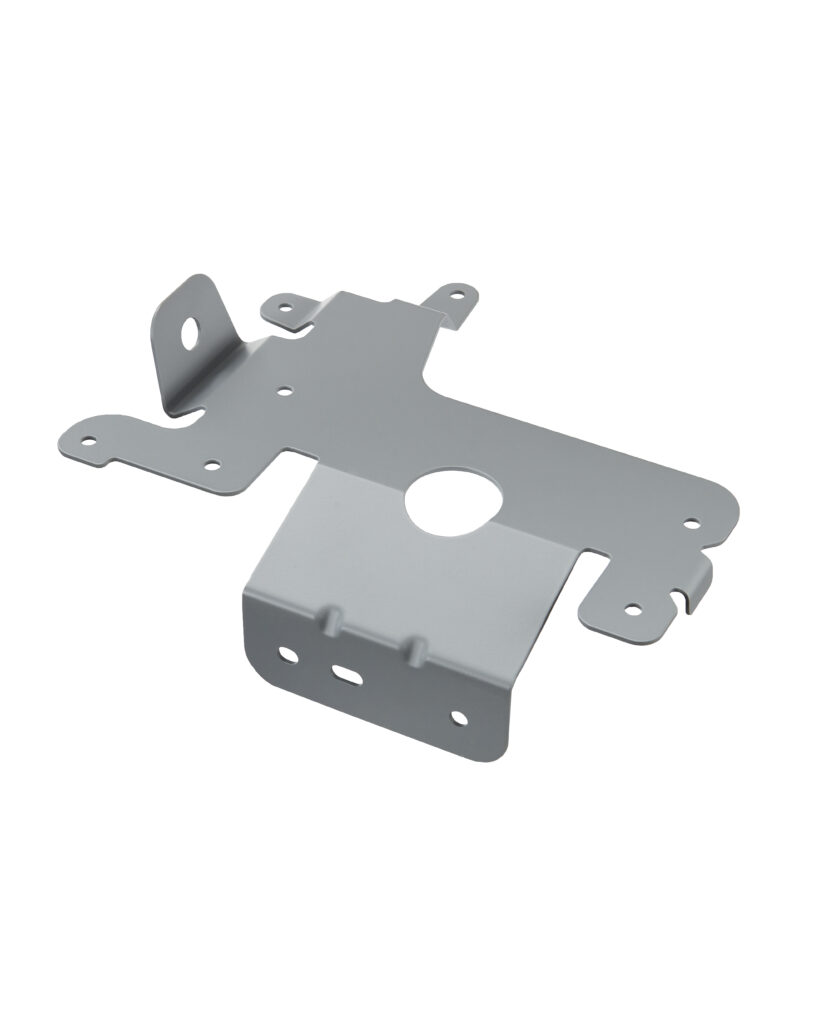

Seating & Interior Brackets

Our Seating and Interior Brackets are designed to meet the rigorous requirements of our customer’s applications. Engineered for tight tolerances and high durability, these brackets provide consistent quality and reliable performance.

Key Features:

- High Precision: Manufactured to tight tolerances, ensuring consistent fitment and long-term reliability.

- Advanced Stamping Capabilities: Incorporates an in-die process to achieve tight trim tolerances and superior shear condition, improving component performance.

Advantages:

- Competitive Edge: Our expertise in tight-tolerance stamping provides a distinct advantage in producing high-quality, precision-engineered components.

- Application-Focused Design: Optimized for various components, where precision, durability, and safety are critical.

Brackets – General Stampings and Assemblies

Our Brackets are designed to deliver exceptional precision, durability, and versatility for automotive and industrial power systems.

Key Features:

- Precision Stamping: Engineered for consistent, high-accuracy production of battery-related brackets and power unit components.

- Versatile Applications: Suitable for auxiliary battery trays, power units, and general stamping needs, supporting a wide range of energy storage solutions.

- Diverse Material Options: Manufactured from high-strength low-alloy (HSLA) steel, aluminum, stainless steel, and aluminized stainless steel – ensuring strength, durability, and lightweight performance while meeting customer specifications.

Advantages:

- Advanced Process Capabilities: Our robust stamping and forming expertise ensures high performance, reliability, and adaptability in evolving power system applications.

- Scalable Production: Designed to support high-volume manufacturing and custom production requirements, ensuring flexibility and efficiency.

- Stamping Capabilities: Eliminates the need for machining while maintaining tight tolerances.

Get the latest from our design, engineering, and manufacturing teams.

Recent News

Amsted Automotive Wins Michigan Manufactured Export of the Year Award with Innovative One-Way Clutch

Amsted Automotive was honored with the Michigan Manufactured Export of the Year award, presented by the Michigan Manufacturers Association (MMA) recognizing the company’s leadership in…

Amsted Automotive Showcases Industry-Leading Manufacturing Capabilities at the 2025 MEMA OE Suppliers Annual Conference

Amsted Automotive will highlight its global engineering and manufacturing capabilities at the 2025 MEMA OE Suppliers Annual Conference November 19-20, 2025, displaying examples and information…

Amsted Automotive Honored with Manufacturer of the Year Award

Amsted Automotive has been named the 2025 John G. Thodis Michigan Manufacturer of the Year – Large Tier by the Michigan Manufacturers Association (MMA). The…

Amsted Automotive Highlight Advanced Metal Forming Capabilities at The Battery Show

Amsted Automotive will showcase its industry-leading metal forming expertise at The Battery Show North America, demonstrating how these capabilities are critical to the performance, efficiency,…